“Accident Prevention is both science and art. It represents, above all other things, control – control of man performance, machine performance, and physical environment. The word ‘control’ is used advisedly because it connotes prevention as well as correction of unsafe conditions and circumstances”. (Heinrich and Granniss, 1959, 4)

In the mid 1920’s a series of theorems surrounding accidental injury were developed (Heinrich and Granniss, 1959, 4). The theorems show that:

(1) industrial injuries result only from accidents;

(2) accidents are caused directly only by;

- the unsafe acts of persons; or

- exposure to unsafe mechanical conditions;

(3) unsafe actions and conditions are caused only by faults of persons; and

(4) faults of persons are created by environment or acquired by inheritance.

Heinrich chronologically reversed the order of these theorems (i.e. the injury is the last to occur) creating the ‘domino sequence’ which he presented in an address before the Down River Section of the Detroit Safety Council, (Heinrich and Granniss, 1959, 14).

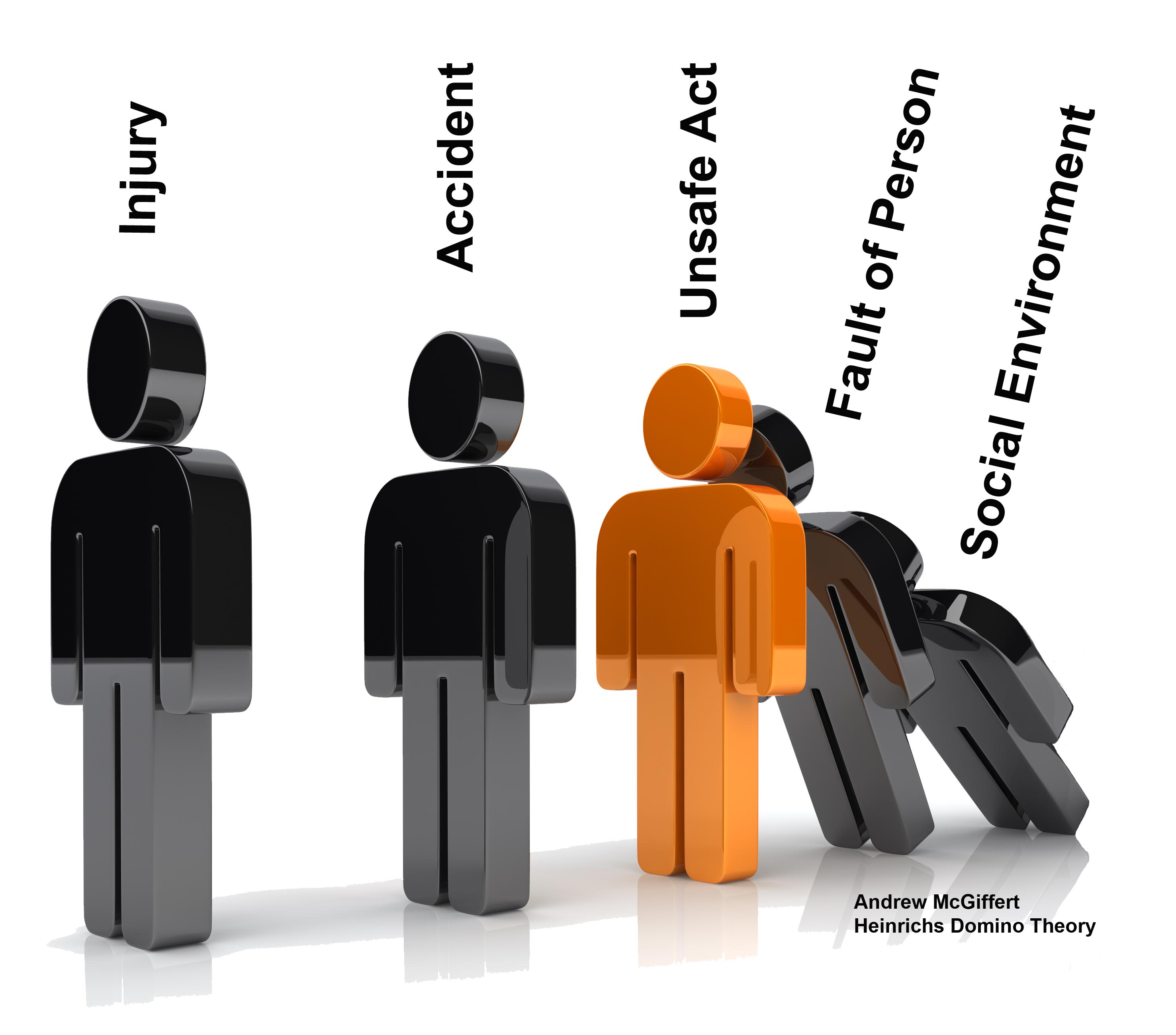

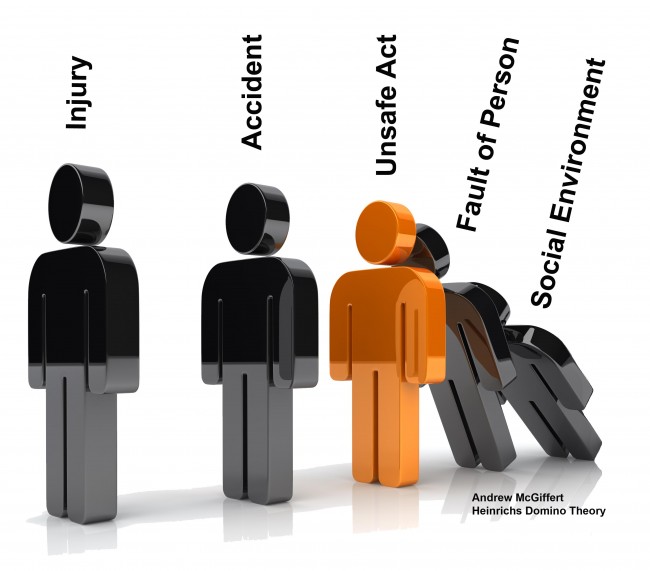

The Domino Sequence is an ‘event based’ or ‘sequential’ accident causation model, used to explain a chain of events that occur in a particular order which result in an injury.

Heinrich’s key factors in the domino sequence of events leading to an injury are shown below:

- Social environment;

- Fault of the person;

- Unsafe acts or conditions;

- Accident;

- Injury.

An unexpected event initiates a sequence of events which lead to an accident, resulting in injury to a person. The injury is invariably caused by an accident and the accident in turn is always the result of the factor that immediately precedes it, (Heinrich and Granniss, 1959, 14). Therefore to prevent an accident from occurring the target of accident prevention is in the central factor – ‘unsafe acts or conditions’.

One of the best ways to see how the factors interact is to view them as a set of dominos. This is shown in the below illustration, like a set of dominos the fall of the first will trigger the fall of the entire row.

This theory implies that the accident is the result of a single root cause. The domino theory is a very simple process, considering only a single chain of events. This may be considered a disadvantage of this model as an accident is usually caused by a range of contributing factors which interact with one another, resulting in an injury, not necessarily in a fixed and logical order.

Sequential models are limited in their capability to explain accident causation in more complex accident or OHS systems (Quershi, 2008), and could be said to be used in order to ‘assign blame’ or determine a single root cause.

“Typically, in these types of (sequential) models , causal factors in an accident which are not linked to technical component failures were classified as human error as a kind of catchall or garbage can” (Hollnagel, 2001).

To support this statement an example of a ‘simple’ incident is shown below. The incident has been analysed using the domino sequence.

An employee within the Point Cook receiving area was requested by his supervisor to quickly move a stack of wooden pallets to the outside loading area for collection as the truck would be arriving soon.

|

Social Environment |

Request by supervisor to action task ‘quickly’ |

|

Fault of Person |

Did not use provided PPE (Riggers gloves) |

|

Unsafe Act or Condition |

Moved pallet using bare hands, ignored safe working practice. |

|

Accident |

Sustained grazes to hands and dropped pallet |

|

Injury |

Broken toes on right foot due to dropping pallet on foot. |

Looking at the incident in the logical and fixed order of the domino sequence it is difficult to not assign blame, either to the supervisor for issuing unsafe direction, or to the employee for not using provided equipment or for not following safe working practices.

Considering each of the factors it becomes apparent that all played a part in the resulting injury and the root cause is not as simple as the ‘first step in the process’. By removing any of the three initial factors this particular injury could not have possibly occurred, as was explained by Heinrich “if the series is interrupted by the elimination of even one of the several factors that compromise it, the injury cannot possibly occur”, (Heinrich and Granniss, 1959, 16).

Using the domino sequence of events it becomes quickly apparent that the failure of man (unsafe acts) is the heart of the problem and methods of control must be directed towards this failure, (Heinrich and Granniss, 1959, 4).

As shown in the example it quickly becomes apparent that the domino sequence is limited in its scope and only provides for the seemingly clear and direct causes of the accident (i.e. the employee using his bare hands to move the pallet and not following the correct working practice). Heinrich was not indicating that by removing this one factor there would be no more workplace accidents, but was pointing out that prevention must first deal with the immediate conditions and circumstances out of which other similar accidents may be created, (Heinrich and Granniss, 1959, 4).

The advantage of this model is that it provides a very quick and simple investigation to determine reasons for the accident. The disadvantage of this model is that it does not allow for effective analysis of the environmental factors – the factors external to the unsafe act. Using this model to review all incidents will not allow the investigator to necessarily uncover the true reasons for the unsafe acts taking place. As written by Dr. Andrew Hopkins in his book Lessons from Longford (Hopkins, A. 2000) “Operators will inevitably make errors sooner than later, if it is possible for them to do so. From a prevention point of view it is better to focus on factors further back along the causal chains which put operators in a position where it is possible for them to make critical errors”. This statement supports the disadvantages of the domino theory in accident prevention.

Heinrich, H.W., and E.R. Granniss. 1959. Industrial Accident Prevention. United States of America: McGraw-Hill Book Company Inc.

Hollnagel, E. 2001. Anticipating Failures: What should Predications be About? In The Human Factor in Systems Reliability – Is Human Performance Predictable? RTO Meeting Proceedings 32, RTO-MP-32, January, Research and Technology Organisation, North Atlantic Treaty Organisation, Cedex, France: RTO/NATO.

Hopkins, A. 2000. Lessons from Longford: The Esso Gas Plan Explosion. Australia: CCH Australia Limited.

Qureshi, Z.H. 2008. A Review of Accident Modelling Approaches for Complex Critical Sociotechnical Systems, DSTO-TR-2094, Defence Science and Technology Organisation. http://www.dsto.defence.gov.au (accessed September 2, 2010).

No Responses